After developing the site concept "Micro Screw Centre Cold Forming" with the reorientation and optimisation of the areas electro-plating shop, incoming goods, hardening shop, maintenance and EJOMAT, the management decided on a concrete expansion plan for the Bienhecke site in Bad Laasphe this spring.

The core area of the planning is the complete renovation of the former production hall A + B, where micro screws were manufactured up to two years ago. The immediate periphery with technical systems and container storage is also being redesigned and renovated. “The benchmark here is also the EJOT standard, as we know it from other locations, such as Herrenwiese in Bad Berleburg”, explains Markus Sauer, who has been in charge of the production planning department at the Bienhecke site since January 1st. All employees can look forward to a modern working environment after completion of the construction work.

In the first construction phase, the dilapidated interior of Hall A + B will be completely renovated: replacement of the floor slab with partial renewal of the foundations, roof, electrics, ventilation and even fire protection. The industrial floor will have underfloor heating, which is operated via the existing gas boiler. Sustainability also plays an important role in the further construction planning. In order to save CO2, the operation of an air-water heat pump and production of electricity via photovoltaics are planned in the second construction phase.

Three main areas in the hall will be restructured and rearranged in the course of the construction work: A self-contained spare parts store with materials for electro-plating, hardening and EJOMAT, an area for maintenance with a welding work station and a separate area for milling and turning work as well as the EJOMAT department for the micro screws.

One point of discussion in the construction planning was the design of the roof for the 35 meter long hall. With version I, the roof shape and height with the row of columns in the hall would not have been taken into account and so the factors known for EJOT standards could not have been achieved (greatest flexibility, modern, friendly working environment and a corresponding external impression). With this version, the machine capacity would have been limited in the EJOMAT department. The planning for version II provided for an elevation of the hall roof by two meters with the same roof pitch (saddle roof). With this version, too, the row of columns in the middle of the hall would still have been necessary, at the expense of flexibility and functionality.

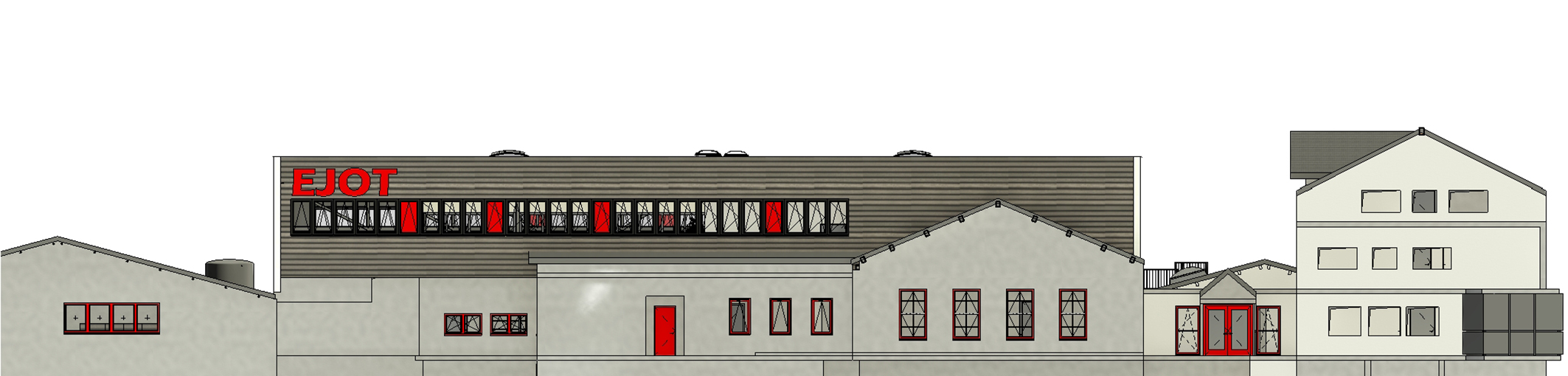

Ultimately, version III was chosen, which provides for the hall roof to be raised by three meters and for a flat roof instead of a saddle roof. This also omits the row of columns. Another advantage is the possibility of more generous illumination of the interior in the area of the roof and the facade. The construction process for this variant is more complex and also associated with additional costs, but in the end, it results in a modern industrial standard that ensures optimal use of the hall complex for years to come. In the course of the construction work, the surrounding and adjacent roofs must also be reinforced to protect against increased snow loads. This is due to the categorisation of snow load zones and the adjustments to the current technical building regulations.

In the directly adjacent outdoor area of the hall, technical systems, containers and a washing area are arranged in a covered area.

A total of 3.9 million euros will be invested in the construction project by 2024. Construction will start in September 2021 with the demolition of the floor slab.

The core area of the planning is the complete renovation of the former production hall A + B, where micro screws were manufactured up to two years ago. The immediate periphery with technical systems and container storage is also being redesigned and renovated. “The benchmark here is also the EJOT standard, as we know it from other locations, such as Herrenwiese in Bad Berleburg”, explains Markus Sauer, who has been in charge of the production planning department at the Bienhecke site since January 1st. All employees can look forward to a modern working environment after completion of the construction work.

In the first construction phase, the dilapidated interior of Hall A + B will be completely renovated: replacement of the floor slab with partial renewal of the foundations, roof, electrics, ventilation and even fire protection. The industrial floor will have underfloor heating, which is operated via the existing gas boiler. Sustainability also plays an important role in the further construction planning. In order to save CO2, the operation of an air-water heat pump and production of electricity via photovoltaics are planned in the second construction phase.

Three main areas in the hall will be restructured and rearranged in the course of the construction work: A self-contained spare parts store with materials for electro-plating, hardening and EJOMAT, an area for maintenance with a welding work station and a separate area for milling and turning work as well as the EJOMAT department for the micro screws.

One point of discussion in the construction planning was the design of the roof for the 35 meter long hall. With version I, the roof shape and height with the row of columns in the hall would not have been taken into account and so the factors known for EJOT standards could not have been achieved (greatest flexibility, modern, friendly working environment and a corresponding external impression). With this version, the machine capacity would have been limited in the EJOMAT department. The planning for version II provided for an elevation of the hall roof by two meters with the same roof pitch (saddle roof). With this version, too, the row of columns in the middle of the hall would still have been necessary, at the expense of flexibility and functionality.

Ultimately, version III was chosen, which provides for the hall roof to be raised by three meters and for a flat roof instead of a saddle roof. This also omits the row of columns. Another advantage is the possibility of more generous illumination of the interior in the area of the roof and the facade. The construction process for this variant is more complex and also associated with additional costs, but in the end, it results in a modern industrial standard that ensures optimal use of the hall complex for years to come. In the course of the construction work, the surrounding and adjacent roofs must also be reinforced to protect against increased snow loads. This is due to the categorisation of snow load zones and the adjustments to the current technical building regulations.

In the directly adjacent outdoor area of the hall, technical systems, containers and a washing area are arranged in a covered area.

A total of 3.9 million euros will be invested in the construction project by 2024. Construction will start in September 2021 with the demolition of the floor slab.